|

Introduction

Glass is

produced by melting together silica, usually in the form of sand, and an

alkaline flux such as soda or potash, with the addition of other

ingredients. Glass was known to the ancient Egyptians though the technique

of blowing glass was not introduced until the Roman period. The

construction of glasshouse and furnace altered considerably over the

years. The spectacular English contribution was the lofty brick

glass-cone, which acted as a chimney for the furnace but also housed the

glassmakers, who worked in teams around the furnace in the centre. The

inside the cone, describes the basic glassmaking techniques, and explains

the mysteries of the rich vocabulary that surround this ancient craft.

Glass

is an artificial, non-crystalline material, categorised as a super-cooled

liquid rather than a solid .As mentioned above the basic ingredient is

silica, usually in the form of a fine sand, to which alkaline fluxes such

as soda or potash are added which bring the melting point down to the

region of 1300 to 1500 degrees C. At this temperature the glass is fluid

like water but before working the temperature is reduced until the glass

has the consistency of honey or treacle .Other ingredients in the

batch, as the mixture of raw materials is called, include lime or lead

oxide, according to the type of glass being made, and a quantity of

cutlet (broken glass), which aids fusion and saves on the costs of

fuel and raw materials. Glass

is an artificial, non-crystalline material, categorised as a super-cooled

liquid rather than a solid .As mentioned above the basic ingredient is

silica, usually in the form of a fine sand, to which alkaline fluxes such

as soda or potash are added which bring the melting point down to the

region of 1300 to 1500 degrees C. At this temperature the glass is fluid

like water but before working the temperature is reduced until the glass

has the consistency of honey or treacle .Other ingredients in the

batch, as the mixture of raw materials is called, include lime or lead

oxide, according to the type of glass being made, and a quantity of

cutlet (broken glass), which aids fusion and saves on the costs of

fuel and raw materials.

To

colour glass, minute quantities of metallic oxides are added to the batch.

About 50 BC it was discovered that molten glass could be blown into a

bubble on the end of a long hollow metal pipe, and present day. After

completion all glass has to be annealed, a very gradual uniform

cooling process which strengthens the glass by removing the stresses that

have built up during manufacture. It is only after annealing that glass is

ready to be decorated by techniques such as engraving or cutting. A close

natural equivalent to glass is the translucent colourless quartz, rock

crystal. Its qualities have been admired and imitated by glassmakers for

centuries and to- day the word crystal is widely used to describe

the best-quality clear glass. Top To

colour glass, minute quantities of metallic oxides are added to the batch.

About 50 BC it was discovered that molten glass could be blown into a

bubble on the end of a long hollow metal pipe, and present day. After

completion all glass has to be annealed, a very gradual uniform

cooling process which strengthens the glass by removing the stresses that

have built up during manufacture. It is only after annealing that glass is

ready to be decorated by techniques such as engraving or cutting. A close

natural equivalent to glass is the translucent colourless quartz, rock

crystal. Its qualities have been admired and imitated by glassmakers for

centuries and to- day the word crystal is widely used to describe

the best-quality clear glass. Top

EARLY

HISTORY

The Roman

author Pliny, writing in the first century AD, tells a delightful story

about how glass was invented. Some Phoenician sailors camped one night on

a beach, lit a fire and set their cooking pots on blocks of natron (soda),

which was the cargo they were carrying. When they awoke the following

morning they found that the heat of the fire had fused the sand and natron

into glass. But nobody knows for certain how glass originated. The

earliest traces have been found in

Mesopotamia from the period 3000 to 2000 BC and from there the art

probably spread to ancient

Egypt.

Before the discovery that glass could be blown on the end of a long hollow

pipe, various forming techniques were used, such as casting and pressing

into moulds, and carving from solid blocks of glass. About 1500 BC the

Egyptians began using a technique called core moulding to make

small vessels for precious ointments and liquids. A core was made from mud

and straw or clay in the shape of the object required and was attached to

the end of a metal rod. It was then dipped in molten glass and trailed

with different colours or it was coated with powdered glass and fired.

Once the glass had cooled the rod was withdrawn and the core picked out.

This technique continued well after the invention of glassblowing. Under

the Romans glassmaking flourished, spreading from its traditional home in

Egypt

and Syria to new corners of the empire such as Germany, France and even

Britain. Top

By far the most significant event was the invention of glassblowing, which

is thought to have occurred in Syria about 50 BC. It led not only to a new

style of glass but also to a great increase in production, so that from

being a luxury product glass became for the first time a common everyday

article which it was not to be again until the nineteenth century. Cups,

bowls, bottles, jars, jugs and vases formed the majority of the output.

Roman glass often has a green or brown tint due to impurities in the raw

materials but in the second century AD it was discovered that those could

be neutralised by the addition of a small amount manganese oxide.

By far the most significant event was the invention of glassblowing, which

is thought to have occurred in Syria about 50 BC. It led not only to a new

style of glass but also to a great increase in production, so that from

being a luxury product glass became for the first time a common everyday

article which it was not to be again until the nineteenth century. Cups,

bowls, bottles, jars, jugs and vases formed the majority of the output.

Roman glass often has a green or brown tint due to impurities in the raw

materials but in the second century AD it was discovered that those could

be neutralised by the addition of a small amount manganese oxide.

THE

TWENTIETH CENTURY

In

the twentieth century there have been such spectacular advances in glass

technology that glass is now being used in areas that would have been

inconceivable one hundred years ago. One striking example is

heat-resistant ovenware, which was introduced in 1915 by the Coming Glass

Works in the

USA under the famous brand name Pyrex. The borosilicate

glass from which it is made has good chemical stability and low thermal

expansion and can therefore withstand sudden changes in temperature. In

the late 1950s a new material was developed, known as Glass Ceramics,

which, like borosilicate glass, is extremely resistant to thermal shock.

Its strength comes from the fact that a certain amount of crystallization

is allowed to take place during the cooling of the molten glass, and its

applications include cooker hobs and windows for coal and gas fires.

Perhaps the most important technical breakthrough has been the

introduction by Pilkington Brothers of St Helens in 1959 of the float

glass process for the manufacture of flat glass.

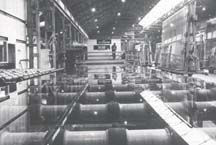

Before float was invented, most flat glass had to be ground and polished

after annealing to remove distortions on the surface caused by the

manufacturing process. In the float glass process, a continuous ribbon of

molten glass from the furnace floats along the surface of a bath of molten

tin in a carefully controlled atmosphere. This not only produces a

perfectly flat glass because the molten tin is flat, but it makes the

laborious grinding and polishing stage redundant because the glass has

become sufficiently hard by the time it leaves the molten tin for its

surface not to be marked by the rollers on which it is taken up and

conveyed to the annealing chamber. Float glass has revolutionised the flat

glass industry and is now used worldwide under licence from Pilkingtons. Top

Before float was invented, most flat glass had to be ground and polished

after annealing to remove distortions on the surface caused by the

manufacturing process. In the float glass process, a continuous ribbon of

molten glass from the furnace floats along the surface of a bath of molten

tin in a carefully controlled atmosphere. This not only produces a

perfectly flat glass because the molten tin is flat, but it makes the

laborious grinding and polishing stage redundant because the glass has

become sufficiently hard by the time it leaves the molten tin for its

surface not to be marked by the rollers on which it is taken up and

conveyed to the annealing chamber. Float glass has revolutionised the flat

glass industry and is now used worldwide under licence from Pilkingtons. Top |